Polytronics

Technology Corporation (PTTC)

in conjunction with DENKA

has now developed a brand new material

technology focused on thermal management. It covers the

following product

lines.

- Thermal

conductive compounds

- Thermal

conductive substrates including IMS and FS

- Thermal

conductive modules

These

technological materials have practical applications in a

large variety

of appliances and products ranging from home to commercial

and industrial

settings.

Thermal

Management

LEDs

wonˇ¦t burn your hand compared to the more common light sources,

but they do produce heat. In fact, thermal management is

arguably the most important aspect of successful LED system

design. PTTC has mastered this working

design in a LED system package, either in a module or substrate

form.

Why

Does Thermal Management Matter?

Excess

heat directly affects both short-term and long-term LED

performance. The short-term (reversible) effects are color

shift and reduced light output while the long-term effect

is accelerated lumen depreciation and thus shortened useful

life.

The

light output of different colored LEDs responds differently

to temperature changes, with amber and red the most sensitive,

and blue the least. (See graph below.) These unique temperature

response rates can result in noticeable color shifts in

RGB-based white light systems if operating Tj differs from

the design parameters. LED manufacturers test and sort (or

ˇ§binˇ¨) their products for luminous flux and color based

on a 15-20 millisecond power pulse, at a fixed Tj of 25˘XC

(77˘XF). Under constant current operation at room temperatures

and with engineered heat mitigation mechanisms, Tj is typically

60˘XC or greater. Therefore white LEDs will provide at least

10% less light than the manufacturerˇ¦s rating, and the reduction

in light output for products with inadequate thermal design

can be significantly higher.

Continuous

operation at elevated temperature dramatically accelerates

lumen depreciation resulting in shortened useful life. The

chart below shows the light output over time (experimental

data to 10,000 hours and extrapolation beyond) for two identical

LEDs driven at the same current but with an 11˘XC difference

in Tj. Estimated useful life (defined as 70% of initial lumen

output) decreased from ~37,000 hours to ~16,000 hours, a 57%

reduction, with the 11˘XC temperature increase.

However,

the industry continues to improve the durability of LEDs

at higher operating temperatures. The Luxeon K2, for example,

claims 70% lumen maintenance for 50,000 hours at drive currents

up to 1000 mA and Tj at or below 120˘XC. (Luxeon K2 Emitter

Datasheet DS51, dated 5/06)

|

What

Determines Junction Temperature?

Three

things affect the junction temperature of an LED:

drive current, thermal path, and ambient temperature.

In general, the higher the drive current, the greater

the heat generated at the die. Heat must be moved

away from the die in order to maintain expected light

output, life, and color. The amount of heat that can

be removed depends upon the ambient temperature and

the design of the thermal path from the die to the

surroundings.

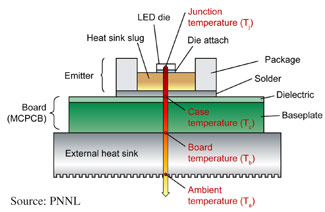

The

typical high-flux LED system is comprised of an emitter,

a metal-core printed circuit board (MCPCB), and some

form of external heat sink. The emitter houses the

die, optics, encapsulant, and heat sink slug (used

to draw heat away from the die) and is soldered to

the MCPCB. The MCPCB is a special form of circuit

board with a dielectric layer (non-conductor of current)

bonded to a metal substrate (usually aluminum). The

MCPCB is then mechanically attached to an external

heat sink which can be a dedicated

|

|

device

integrated into the design of the luminaire or, in some cases,

the chassis of the luminaire itself. The size of the heat

sink is dependent upon the amount of heat to be dissipated

and the materialˇ¦s thermal properties.

Heat

management and an awareness of the operating environment

are critical considerations to the design and application

of LED luminaires for general illumination. Successful products

will use superior heat sink designs to dissipate heat, and

minimize Tj. Keeping the Tj as low as possible and within

manufacturer specifications is necessary in order to maximize

the performance potential of LEDs.

|

|

6F-3,

No.9 Prosperity RD. I, SBIP, Hsin-Chu, Taiwan, 300

TEL:886-3-5643931ˇ@FAX:886-3-5644624

|